Technology

We continuously expand our production capacities and innovate the technology.

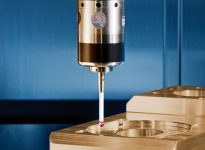

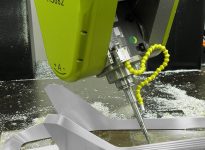

EQUIPMENT aND QUALITY

CNC cutting and machining of plastics in quality according to ISO 9001 standard

- precise cutting on automatic saws up to 100 mm thickness

- grinding and calibration of thickness with 0.1 mm accuracy

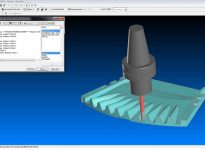

- milling from 3 to 5 independently controlled axes with rotating and tilting tables

- turning, including parts with eccentric slots (head with powered tooling)

- surface finishing of parts and cut surfaces (protection by varnish impregnation)

- mounting threaded metal inserts into machined plastic parts

- marking and printing of parts

- bonding the components by glue to assemble the segments

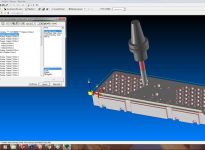

CAD/CAM SOFTWARE SYSTEMS

These increase our efficiency. We use the latest software – CAD/CAM systems that allow us to work in a flexible way.

EQUIPMENT USED

We have 15 CNC-controlled machines with 3 to 5 continuously controlled axes, and other single-purpose machines for machining of plastic materials including an optical table for measuring of tools geometry.

EXAMPLES OF OUR EQUIPMENT

- OLYMPUS DIGITAL CAMERA

- OLYMPUS DIGITAL CAMERA